Ingredient Masters Batching System

Description

Ingredient Masters Ingredient Batching System. Only used for a short period. This 2010 system consists of 20 removable 28-cubic-foot ingredient dispensers, 20 screw feeders with helix screws, one powered infeed roller conveyor, five scaling roller conveyors, one powered outfeed conveyor with a checkweigh station, and one PLC controller that controls the entire system’s operation.

A custom-engineered structural steel frame with a top-access walkway supports the system’s components and allows operators easy access to the dispensers for refilling them. It also creates two 10-dispenser parallel rows with about 50 inches of space between them. The powered infeed and outfeed conveyors along with the five scaling conveyors form a straight line between the two dispenser rows. This results in five batching zones that receive product from the four adjacent ingredient dispensers (two from each row). The conveyor moves the batch barrels along the line, stopping at each batching zone’s weigh station to collect material from the appropriate ingredient dispensers in each batching zone. The system’s PLC controller has a flat touchscreen that allows an operator to easily call up the various recipes, monitor the system’s components and operation, and manage inventory.

- The polyethylene ingredient dispensers are approved for use in USDA, FDA, and 3-A Dairy applications. Dispensers that hold a sticky, non-free-flowing ingredient use air pads and vibrators to aid material discharge. A dust collection port connected to the company’s dust control system is inside each dispenser and removes dust generated during refilling.

- At each weigh station, a screw feeder bulk-and-dribble-feeds the ingredient into a batch barrel. The company sets the maximum feed rate for each dispenser according to the ingredient it contains. A computer-controlled cutoff valve on the end of each screw feeder closes when the feeder stops, preventing material from the screw flight from falling into the barrel. Additionally, a dust collection port mounted above each weigh station near the screw feeders’ discharge collects any dust generated during feeding.

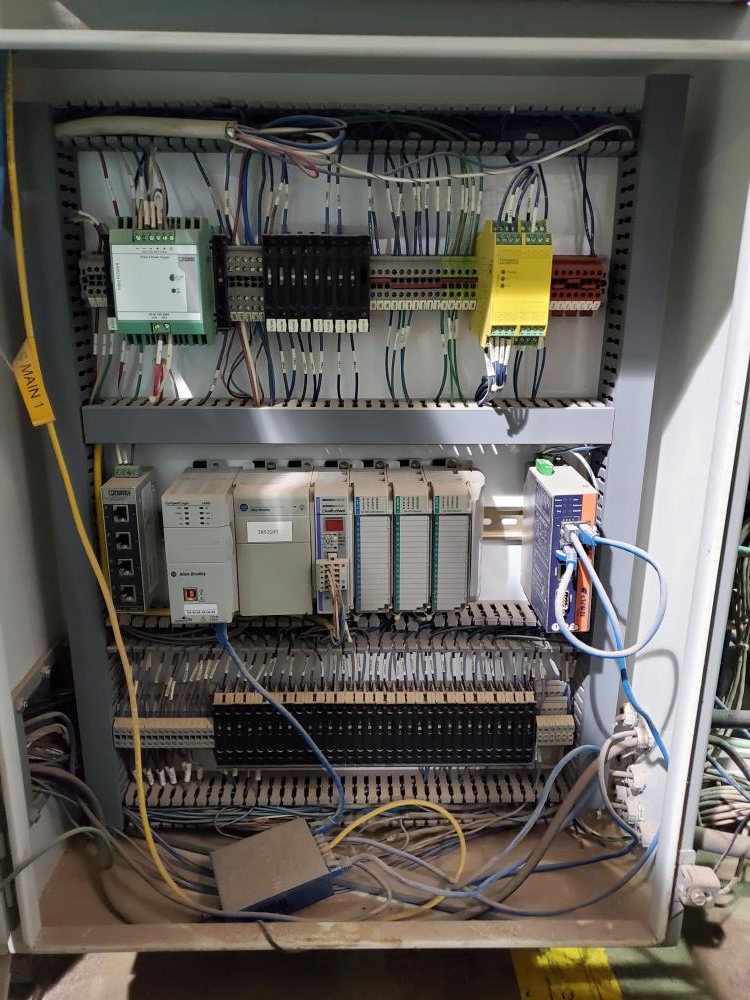

- The system’s PLC controller has a flat-panel touchscreen that allows an operator to easily call up the various recipes, monitor the system’s components and operation, and manage inventory. For quality control, if an ingredient runs low during operation or an ingredient being filled into a batch barrel falls outside the system’s ±0.5-percent accuracy range, the PLC sounds an alarm and stops the system until an operator acknowledges it. The PLC also generates a tag that gives the lot number of each individual ingredient used in a recipe, allowing the company to track lot numbers from the ingredient manufacturer all the way into the finished product to provide complete quality control. The PLC is connected to the company’s plant-wide computer system, allowing remote monitoring of the batching process, automatic inventory control, and recipes to be downloaded directly from a central location rather than input manually at the PLC.

- Automating the weighing and batching process To batch a product using the new system, an operator loads empty batch barrels onto the infeed conveyor, then accesses the PLC and calls up one or more recipes. For each recipe, the operator inputs the batch size, and the PLC calculates the percentages and weights for each ingredient. Next, the operator pushes the start button, and the infeed conveyor moves an empty barrel to the first scaling conveyor, which moves the barrel to the first weigh station. Once the barrel is in position, the PLC activates the screw feeders one at a time to feed the required ingredients into the barrel.

- After the first weigh station’s ingredients have filled into the barrel, the conveyor moves the barrel to the next scaling conveyor, which moves it to the next weigh station. At the same time, the PLC calls up the second recipe in the queue (which may be the same as the first or a different one), and a second barrel moves into the system and is positioned at the first weigh station. When both barrels have been filled, the conveyors advance each barrel to the next weigh station, and the process continues for each recipe in the queue, with the barrels advancing through the system like a train, stopping at each weigh station to receive the required ingredients.

- After a barrel exits the system onto the outfeed conveyor, it’s positioned on the checkweigh station so the PLC and operator can verify the total batch weight. The operator then covers the barrel, attaches a printed lot tag, and puts the barrel on a pallet that’s moved to the mixing area. The system, which is programmed so that a barrel can receive ingredients from one to 20 dispensers, can complete a batch containing five ingredients in about 6 minutes, depending on each ingredient amount. This also comes with a dust collection piping.

Specifications

Financing Options

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)

_thumb.jpg)